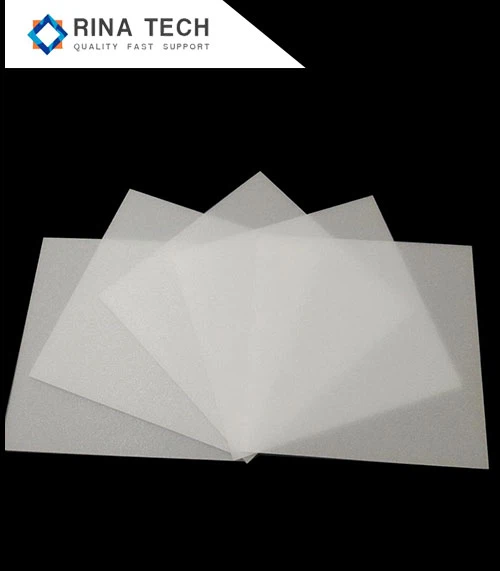

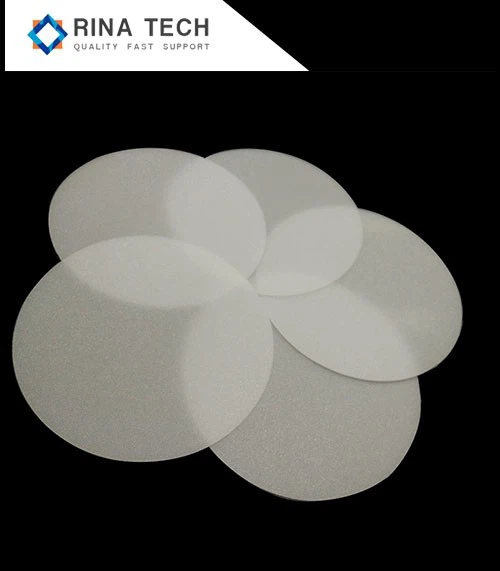

Diffuser Sheet For Led

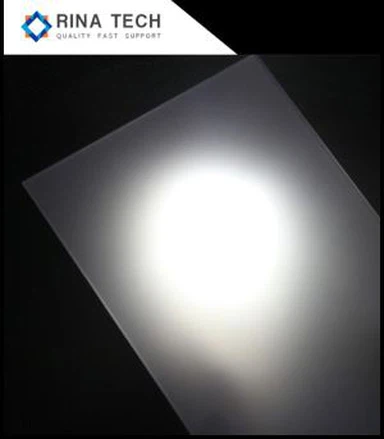

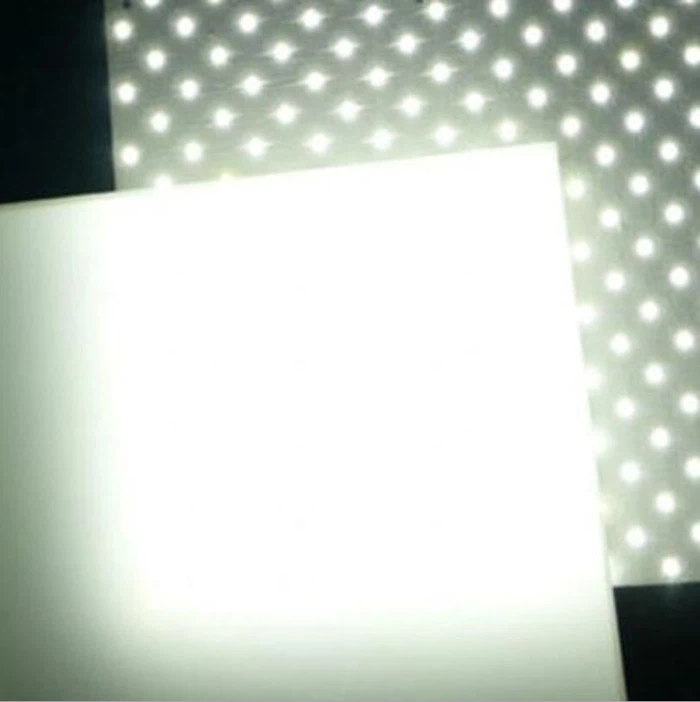

This high-quality optical material diffuser adopts advanced surface treatment technology, which can efficiently transform point light source or line light source into soft and uniform surface light source. The unique micro-structure enhancement design not only improves the optical transmittance, but also effectively produces scattered light to avoid the glare caused by direct light.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

what is diffuser sheet?

A diffuser sheet is a critical component in many lighting and display systems. Its primary purpose is to transform concentrated or directional light sources, such as LEDs or fluorescent lamps, into a more evenly distributed and softened illumination.

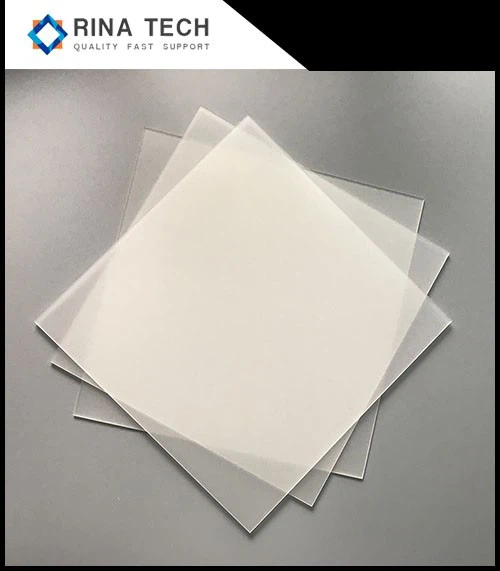

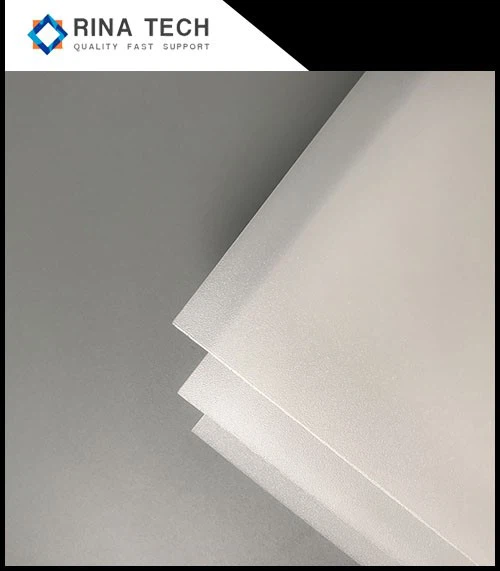

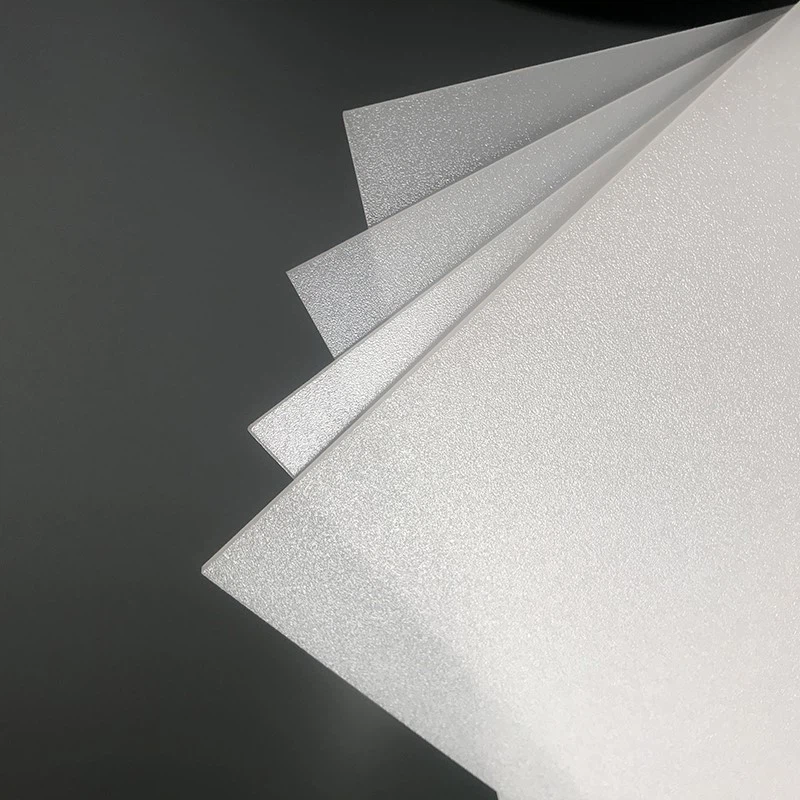

These sheets are typically made from transparent or translucent materials like acrylic, polycarbonate, or polyethylene terephthalate (PET). The surface of the diffuser sheet is engineered with specialized textures, coatings, or patterns to optimize the light diffusion properties.

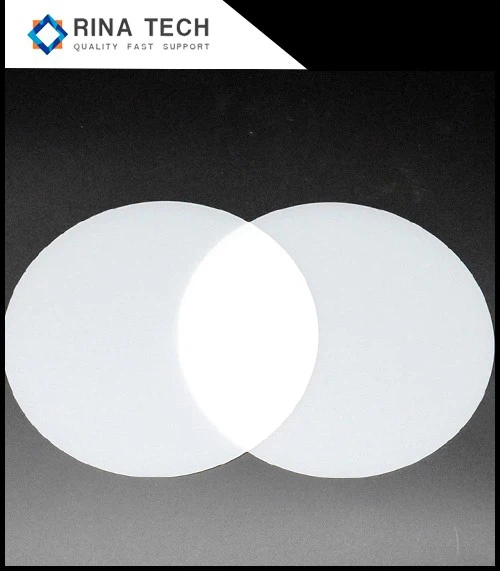

By passing the light through the diffuser sheet, the brightness and intensity of the illumination is evenly dispersed across a larger area. This helps to eliminate hot spots, shadows, and other uneven lighting effects that can occur with direct light sources. The result is a softer, more visually comfortable and aesthetically pleasing lighting or display environment.

The ability to customize the size, thickness, optical properties, and surface patterns of diffuser sheets allows manufacturers to tailor the light diffusion characteristics to meet the specific requirements of each application. This flexibility makes diffuser sheets an essential component in modern lighting and display technologies.

Overall, the diffuser sheet plays a crucial role in transforming concentrated light sources into uniform, comfortable, and visually appealing illumination or visual outputs across a wide range of industries and applications.

advantages of diffuser sheet

1. Uniform Lighting Distribution:

Diffuser sheets help create a more even and consistent distribution of light across a surface. They eliminate hot spots, shadows, and uneven brightness that can occur with direct light sources.

2. Glare Reduction:

By scattering the light, diffuser sheets help reduce glare and eye strain. This makes the lighting more comfortable and suitable for prolonged viewing.

3. Improved Aesthetics:

The diffused and softened lighting created by diffuser sheets results in a more pleasant and visually appealing lighting environment. This is especially important in applications like displays, signage, and interior lighting.

4. Enhanced Light Efficiency:

Diffuser sheets can help improve the overall light efficiency of a system by minimizing light losses due to uneven distribution. This can lead to energy savings.

5. Design Flexibility:

Diffuser sheets come in a variety of materials, thicknesses, and surface patterns. This allows designers and engineers to customize the light diffusion characteristics to meet the specific needs of each application.

6. Cost-Effectiveness:

Compared to more complex optical solutions, diffuser sheets are generally a cost-effective way to improve the lighting quality and uniformity in many applications.

7. Durability:

Many diffuser sheet materials, such as acrylic and polycarbonate, are highly durable and resistant to scratches, UV exposure, and other environmental factors.

8. Versatility:

Diffuser sheets can be used in a wide range of lighting and display applications, from LED fixtures to LCD panels, making them a versatile solution for numerous industries.

product process of diffuser sheet

1. Material Selection:

The first step is to select the appropriate base material for the diffuser sheet, such as acrylic, polycarbonate, or PET. The choice depends on factors like optical clarity, durability, cost, and the specific application requirements.

2. Surface Treatment:

To achieve the desired light diffusion properties, the surface of the diffuser sheet material is often treated or textured. This can involve processes like:

- Embossing: Creating a micro-structured surface pattern

- Coating: Applying a specialized diffusion coating

- Etching: Using chemical or mechanical processes to create a matte or diffused surface

3. Sheet Forming:

The diffuser sheet material is then formed into the desired shape and thickness. Common manufacturing methods include:

- Extrusion: Continuously extruding the sheet material

- Casting: Pouring the material into a mold and allowing it to solidify

- Cutting: Cutting sheets from larger panels or rolls of material

4. Quality Control:

Rigorous quality control measures are implemented throughout the manufacturing process to ensure consistent optical and physical properties of the diffuser sheets, such as:

- Optical testing: Measuring light transmission, haze, and other optical parameters

- Dimensional inspection: Verifying thickness, flatness, and other physical dimensions

- Visual inspection: Checking for defects, scratches, or other imperfections

5. Packaging and Delivery:

Finally, the finished diffuser sheets are carefully packaged, labeled, and prepared for delivery to customers or for integration into the final lighting or display products.

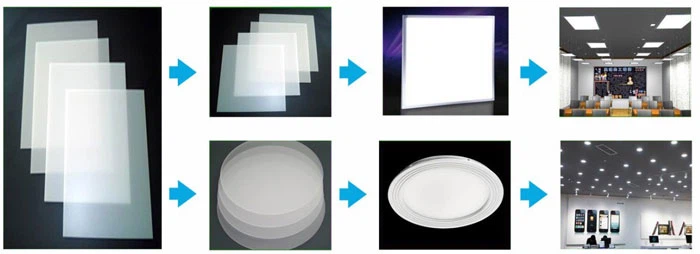

application senior of diffuser

1. Architectural Lighting Design:

Senior lighting designers and architects utilize diffuser sheets to create soft, glare-free lighting environments in commercial, residential, and public spaces. They leverage the light diffusion properties to achieve uniform illumination and enhance the overall aesthetic appeal.

2. Display Technology Development:

Senior engineers and researchers in the display industry, such as those working on LCD, OLED, and projection technologies, use diffuser sheets to optimize the visual quality, contrast, and viewing experience of their displays.

3. Luminaire and Fixture Design:

Senior product designers and engineers in the lighting industry incorporate diffuser sheets into the development of LED, fluorescent, and other types of luminaires and lighting fixtures. This helps them achieve the desired light distribution and uniform illumination.

4. Medical and Scientific Instrumentation:

In the medical and scientific fields, senior researchers and engineers use diffuser sheets in the design of specialized instruments, such as microscopes, surgical lighting, and diagnostic equipment, to create shadowless, glare-free illumination for improved visibility and precision.

5. Automotive and Transportation Lighting:

Senior lighting engineers in the automotive and transportation industries leverage diffuser sheets to develop headlights, taillights, and interior lighting systems that provide uniform, comfortable illumination for drivers and passengers.

6. Stage and Event Lighting:

Senior lighting directors and designers in the entertainment industry use diffuser sheets to create stunning visual effects, uniform stage lighting, and seamless projection surfaces for various live events, theater productions, and concert performances.

7. Signage and Advertising:

Senior marketing and design professionals utilize diffuser sheets in the development of backlit signage, advertising displays, and other visual communication tools to ensure even light distribution and enhance the visual impact.

about us

We are RINA TECH.

Our vision is to be the world's first-rate provider of optical solutions, supply chain and manufacturing solutions. We are a global high-tech company specializing in the research, development, production and sales of optical materials, providing customers with one-step optical lighting solutions. Was established in Hong Kong in 2011, and after years of rapid development, RINA Technology has set up an office and factory in Shenzhen. Currently, we are working with companies such as Toyota, BOE, FLEX, Xiaomi, Siemens, and Coca-Cola , etc. We have made many breakthroughs in research and manufacturing, and have gained a good reputation from many oversea customers. Through sustainable business operations in more than 30 countries and territories around the world, we provide technology innovation, supply chain and manufacturing solutions to various industries and end markets. Our mission is to provide our customers with superior products that create value and improve people's lives. " Our Union's power ,makes the world going better!

certificate

shipping and payment

custom feedback

FAQ

Q1: Are you an Engraving diffuser plate manufacturer?

Yes, we are. You can check more on our website:www.rinalgp.com

Q2:Can you give me an Engraving diffuser sample order?

Sure, we accept sample orders.

Q3: How long can I get my order?

The lead time is 3-7 working days for samples and 7-15 working days for bulk orders. Sometimes it is shorter or longer according

to stock and quantity. And shipping time is around 5-30 working days depending on the shipping methods you choose.

Q4: What is the warranty time for your products? If any is broken, what I will do?

2-3 years warranty for most of our products. During warranty time, we will arrange the new replacement to you for free of charge.

Q5: Can I get OEM/ODM customized products for special applications?

Of course, we provide OEM and ODM service, design, and produce per customers' requirements. Such as different lengths, different

voltages,s and higher lumen efficiency of led strips, different sizes of led panels, tubes; special/unusual materials for some

lights, etc.

Q6: What kinds of payment methods do you accept?

T/T bank transfer, West Union and Paypal.

Q7: What kinds of shipping methods do you use?

Sea: seaport to seaport, cheap, long time, suitable for big volume orders

Air: airport to airport

Global express DHL, UPS, FedEx, EMS, TNT: door to door, mostly used, 3-7 working days delivered.

Kinds of Post air mail etc: for small packages below 2kgs, 25-30 working days.

Hot Tags: diffuser sheet for led suppliers, factory, customized, price, in stock, digital display ad examples, indoor lcd advertising display, outdoor lcd display manufacturers, Outdoor digital signage, High Brightness Display Screens, outdoor lcd advertising display