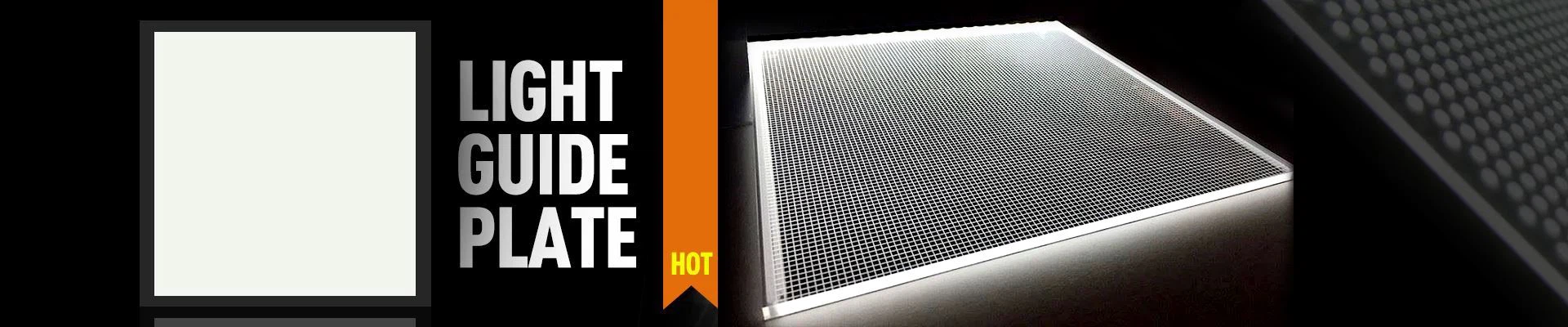

High-brightness Microstructure Light Guide Plate

Product Name: High-Brightness Microstructure Light Guide Plate

Thickness: Customizable for sizes greater than 0.5mm

Dimensions: Customizable

Advantages: Compared to standard light guide plates, this product improves brightness by approximately 30%

Stable performance

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Products Description

High-brightness microstructure light guide plate

High-brightness microstructure light guide plate product introduction

The high-brightness microstructure light guide plate (HBLGP) is a novel optical component crafted using advanced optical design and precision manufacturing processes. Its unique microstructured surface design efficiently guides and controls light propagation, achieving uniform, high-brightness illumination.

In LCD backlight units, HBLGPs convert point or line light sources into surface light sources, significantly improving screen brightness and uniformity, providing users with a clearer, more vivid visual experience. When used in advertising light boxes, they create vibrant, lifelike images, effectively attracting viewers' attention.

Advantages of High-Brightness Microstructure Light Guide Plates

Ultra-High Brightness: Its precisely designed microstructure efficiently focuses and evenly distributes light, increasing brightness by 30%-50% compared to traditional light guide plates, meeting the stringent requirements for high-brightness displays and lighting.

Energy-Efficient: Its superior optical performance reduces light source power requirements while achieving high brightness output, saving 20%-30% energy compared to similar products and embracing environmental protection.

Lightweight and Portable: Utilizing advanced manufacturing processes, the plate can be reduced to a thickness of 1-3mm,

High-brightness microstructure light guide plate production process

Material Selection: Optical-grade polycarbonate (PC) or acrylic (PMMA) is used as the substrate material to ensure excellent optical properties and physical stability. These materials offer high light transmittance, low haze, and excellent impact resistance.

Mold Design and Manufacturing: Based on product design requirements, high-precision microstructure molds are designed using computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. The mold surface microstructures are precisely engineered to the micron level

Injection Molding: Optical-grade plastic pellets are melted at high temperatures and injected into a microstructured mold cavity. Cooling and molding under high pressure creates a precise microstructure pattern on the light guide plate surface. Parameters such as temperature, pressure

Surface Treatment: The molded light guide plate undergoes surface treatments such as hardening and anti-glare treatment. Hardening increases the surface hardness and wear resistance of the light guide plate; anti-glare treatment reduces light reflection

Optical Inspection and Quality Control: We utilize specialized optical testing equipment to thoroughly inspect the light guide plates for brightness, uniformity, transmittance, and other optical properties. We also inspect the product's appearance for defects

Long Life and High Stability: Made from high-quality optical-grade materials with excellent weather and aging resistance, it boasts a lifespan of over 50,000 hours under normal operating conditions, ensuring stable and reliable performance.

Four Core Application Scenarios for High-Brightness Microstructured Light Guide Plates (HB-MLGP)

HB-MLGP, with its micron-scale optical structure design at its core, offers high light transmittance (over 85%), ultra-thin form factor (down to 0.3mm), and environmental adaptability. It serves four key sectors: consumer electronics, automotive, commercial, and industrial. It addresses the core requirements of brightness, uniformity, power consumption, and reliability across these scenarios. It is a key component for achieving precise control of light efficiency in modern optical systems. In the future, its application will expand towards nanoscale structures and integration, driven by technologies such as flexible displays and AR/VR.

Customized parameters of high-brightness microstructure light guide plates

| Material: PS/PP/PMMA |

| Thickness options: 3.0mm/4.0mm, etc. |

| Light distribution |

|

|

|

|

|

|

RINA TECHNOLOGY

is a high-tech enterprise specializing in research, development, production ,

sales of Optical LED products and provide the one step optical lighting solution for customers.Established in 2011, Hong Kong, after years of rapid development, Rina Tech has settled office and factory in Shenzhen,and has professional senior technicians and qualified managers,has a talented team for product research and designing.

Nowadays, we have laser cutting machines, printers, film cutting machines, injection molding equipments,high-standard assembly workshops, BM-7 clean machines and other advanced equipments.Our factory daily output is more than 80000pcs. to cater for the market at home and abroad.

With years of unremitting effort,RINA TECH has passed get the Registration Certificate ofCustoms Declaration Unit of the People's Republic of China , National Credit Cultivation Certificate and Get our own Brand already.

We has made many breakthroughs in researching and manufacturing and hasobtained lots of good reputation from oversea customers.

Now we has cooperated with and become strategic partner of some famous enterprises such as LG, Samsung, Lenovo etc."Living on Sincerity, following with Market, Advancing by Specialty" is our eternal philosophy,and the company motto is "Good at Production, Good for Society".

We look forward to cooperating with you to make the world better and future brighter!

FAQ

1. What is the working principle of High-brightness microstructure light guide plate?

High-brightness microstructure light guide plate works based on the principle of total internal reflection and light scattering. The microstructures on its surface disrupt the total internal reflection of light within the plate, causing the light to scatter outwards. By precisely controlling the shape, size, and distribution of these microstructures, the light can be evenly guided and emitted from the surface of the plate, achieving high - brightness and uniform illumination.

2. How does High-brightness microstructure light guide plate compare with traditional light guide plates?

Compared with traditional light guide plates, High-brightness microstructure light guide plate offers significant improvements. It has a much higher brightness, with an increase of 30% - 50% in general. The light uniformity is also superior, reaching over 90%, while traditional ones may have obvious dark areas or uneven lighting. Additionally, it is more energy - efficient, thinner, and has a longer service life.

3. In which applications is High-brightness microstructure light guide plate most suitable?

High-brightness microstructure light guide plate is highly suitable for a wide range of applications. It is commonly used in LCD backlight modules to enhance display quality, in advertising light boxes to make the content more eye - catching, in automotive instrument panels for better visibility at night, and in various high - end lighting fixtures that require high - brightness and uniform illumination.

4. What are the main factors affecting the performance of High-brightness microstructure light guide plate?

The main factors affecting its performance include the quality of the base material, the precision of the micro - structure design and manufacturing, and the surface treatment process. High - quality optical materials ensure good light transmittance. Precise micro - structures are crucial for efficient light guiding, and proper surface treatment can improve anti - glare and wear - resistance, all of which impact the overall brightness, uniformity, and lifespan of the light guide plate.

5. How to install High-brightness microstructure light guide plate correctly?

When installing, first ensure that the installation environment is clean to prevent dust and debris from affecting the optical performance. Align the light guide plate with the corresponding installation slots or fixtures accurately. When connecting the light source, make sure the connection is secure and the light source is evenly distributed around the edge of the light guide plate. Avoid applying excessive force during installation to prevent damage to the thin and fragile light guide plate.

Hot Tags: high-brightness microstructure light guide plate suppliers, factory, customized, price, in stock