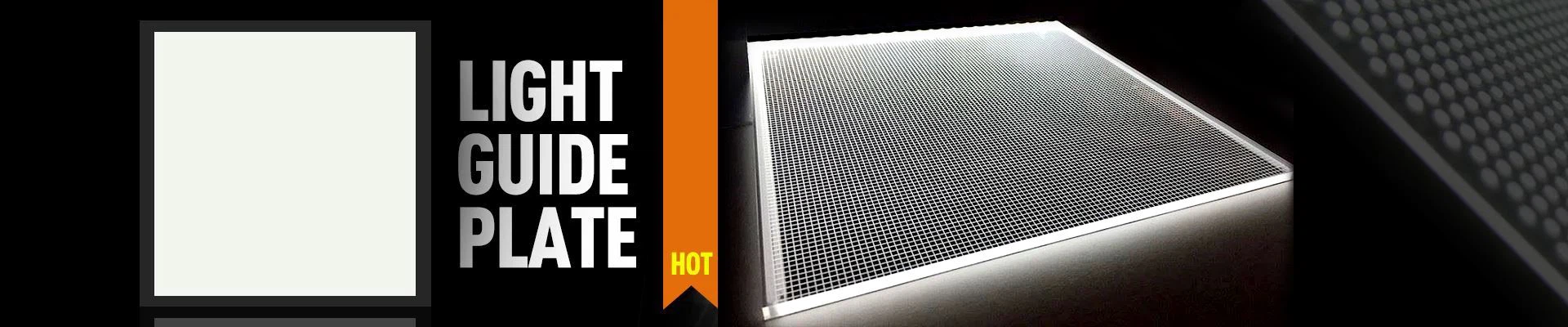

High Brightness LED Guide Plate

RINA TECH light guide plate is a functional plate made of optical grade materials (such as acrylic, PC, etc.). Its core principle is to use the refraction, reflection and scattering of light to evenly transmit and diffuse the light emitted by point light source or line light source (such as LED lamp beads) to the entire plate surface, thus realizing the optical element of "surface light source" effect.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Products Description

1. Definition of light guide plate

Light guide plate is an optical functional plate mainly used in the field of lighting and display. It is usually made of highly transparent optical grade materials, such as highly transparent plastics such as acrylic (PMMA) or polycarbonate (PC). These materials are widely used in backlight sources, advertising displays, flat panel lights, LED lamps, and various light boxes and lighting decorations due to their excellent optical properties, processing convenience and durability.

The core principle of light guide plate is based on the optical refraction, reflection and scattering phenomena. Its main function is to design and process the light emitted by point light sources or line light sources, such as LED lamp beads, so that the light is repeatedly refracted and reflected inside the plate, and finally the light is evenly distributed and diffused, forming the effect of "surface light source". This can not only enhance the uniformity of lighting, but also improve the visual comfort and uniformity of brightness, and achieve the ideal lighting effect.

The workflow of the light guide plate can be briefly described as follows: the light source emits light, and after entering the interior of the light guide plate, part of the light is guided to the plate surface through internal reflection and refraction. The specially designed light guide structure makes the light scattered and emitted on the plate surface, thereby achieving uniform light emission on the entire plate surface. In practical applications, in order to achieve the best optical effect, the light guide plate is usually used in conjunction with auxiliary materials such as diffusion film and reflective film to optimize the distribution of light and enhance brightness.

One of the key structural elements of the light guide plate is the design of the light guide points on its surface or inside. These light guide points can be manufactured using different manufacturing processes, including laser engraving, inkjet printing, microstructure textures, etc. Its core function is to destroy the total reflection condition of light, and by creating tiny disturbances on the surface of the light guide point or block, part of the light is transformed from the total reflection state to the emission state, thereby achieving light scattering and emission. The shape, size, distribution and density of the light guide points have a direct impact on the light guide effect.

In addition, the transmittance of the material used for the light guide plate is also a very critical parameter. The transmittance of the ideal light guide plate material should reach more than 90% to ensure the maximum transmission and scattering effect of light energy and reduce light energy loss. The layout and distribution accuracy of the light guide points are also directly related to the uniformity, brightness and imaging effect of the light. Excellent light guide plate design can achieve uniform light distribution in different areas through precise microstructure control, avoid bright spots or dark areas, and ensure that the final halo and light uniformity meet the requirements of high-quality lighting and display.

In general, the light guide plate has become an indispensable core optical component in lighting and display technology through clever material selection and structural design, combined with optical principles, and provides a basic guarantee for the realization of efficient, uniform and energy-saving surface light sources.

2. The role of light guide plate

Light guide plate plays a vital role in lighting and display technology. Its core function is to optimize the output form of light source to achieve efficient, uniform and comfortable lighting effect. Specifically, these functions can be broken down into the following aspects:

Light transmission

One of the basic functions of light guide plate is to efficiently transmit the light emitted by light source (such as LED lamp beads) along the length or width of the plate. This process takes advantage of the excellent optical properties of light guide plate to ensure that the light is reflected and refracted multiple times inside, effectively guiding the light energy along the predetermined path to the area that needs to be illuminated. During the transmission process, the higher the light transmittance of the light guide plate material, the less light loss, thereby improving the overall transmission efficiency and brightness output. In addition, good optical design can also reduce the scattering loss of light and ensure that more light energy is effectively used.

Light homogenization

The light emitted by the original point light source (such as LED dot matrix) usually forms a concentrated or uneven bright spot, resulting in the problem of "light spot" effect and uneven lighting. The light guide plate scatters these concentrated lights through the light guide points (microstructure patterns, laser engraving points, printed dots, etc.) on the surface or inside to form a uniformly distributed lighting surface. The reasonable layout of the light guide points and their microstructure design can break the state of total reflection of light, so that the light in different areas is evenly emitted, avoiding the unsightly problems such as uneven brightness and stripes in different areas, thereby achieving a natural and uniform surface light effect.

Light diffusion

In order to achieve comfortable and directionally controllable lighting, the light guide plate also has the function of controlling the angle of light emission. Through the cooperation of microstructure patterns or diffusion films, light can be emitted at a specific angle, intensity and distribution, such as mainly emitting light from the front, thereby reducing glare and stray light, reducing visual stimulation to people, and improving the comfort of lighting. This precise light control is especially important in applications such as backlit displays, flat panel lights, and light boxes, which can not only ensure sufficient brightness, but also avoid visual interference caused by unnecessary light scattering.

Space saving and lightweight design

The emergence of light guide plates has greatly promoted the lightweight and thin development of lighting equipment. Compared with traditional backlight sources (such as fluorescent tubes or light boxes), light guide plates can be used with ultra-thin LED light sources to significantly reduce the thickness of the overall device, achieving the design goal of "lightness and thinness". This not only improves the aesthetics and portability of the device, but also provides more flexible and diverse design solutions for architectural decoration, indoor lighting, electronic display and other fields. The compact structure of the light guide plate enables the device to achieve higher space utilization, meeting the modern dual needs of high appearance and space saving.

3. Application scenarios of light guide plates

Light guide plates are widely used in scenarios that require surface light sources due to their characteristics of "uniform light, lightness, and energy saving". Common fields include:

Display equipment:

Backlight modules of liquid crystal displays (LCDs) (the core optical components of LCD displays, responsible for providing uniform light sources for the screen);

Advertising light boxes (such as ultra-thin light boxes, magnetic light boxes), luminous signs, electronic display screens, etc.

Lighting fields:

Indoor lighting (such as panel lights, grille lights, ultra-thin chandeliers);

Landscape lighting (such as luminous floor tiles, stair step lights, contour lights);

Indicator lighting (such as emergency indicators, channel signs, instrument panel backlights).

Consumer electronics:

Screen backlights of mobile phones, tablet computers, and laptops;

Display backlights of small devices such as smart watches and electronic dictionaries.

Other fields:

Medical equipment (such as X-ray film viewing lights, auxiliary light sources for surgical shadowless lights);

Automotive industry (such as in-car atmosphere lights, instrument panel backlights, and door welcome lights).

Our Certificates

Delivery

1. Packaging for slim backlight panel

Internal: Poly Bag

External: Carton

Or can depend on your demand

Shipping

Our Services

Our Advantages:

Various Production Line : We provide a wide range of lcd led displays, hot smart products, promotional gifts for your customers, everything we offered are easilly customized with your logo or your company information for advertising them.

Very Competitive Price: We specialized in customize all high quality promotional items for you and can help you meet any requirements with the most reasonable price and excellent service.

Dedicated Service: We reply every enquiry within 8*3 hours and try our best to meet the demand of the custmer's order.

Why choose us:

If any items get you interested, please send feedback to our email or chat on trade manager,if you can't find what you require on the website, give us email or leave a message. Our custmer service will soource it for you to make great .Thank you.

Hot Tags: high brightness led guide plate suppliers, factory, customized, price, in stock