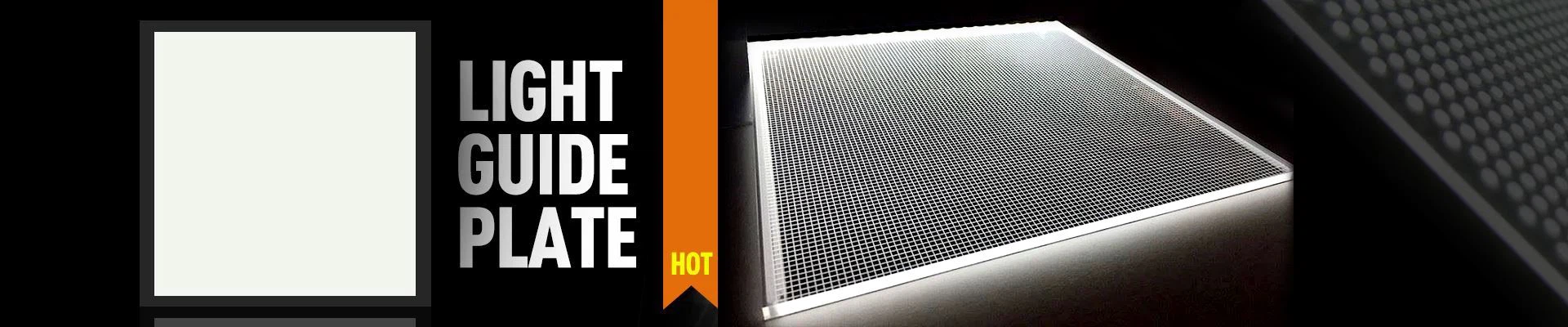

LCD Backlight Light Guide Plate

Product Discription: Light Guide Plate PMMA Recycled Acrylic Sheets LED Light Guide Panel is a lightweight substitute for glass that has better optical quality and is more economical. It provides low distortion and will not yellow after prolonged exposure to sunlight. It offers four times more...

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Rina Technology Co., Ltd. is one of the leading manufacturers and suppliers of lcd backlight light guide plate in China. Welcome to wholesale durable products in stock here and get quotation from our factory. All customized products are with high quality and low price.

Products Description

LCD backlight light guide plate

| Name | lcd backlight light guide plate |

| Design | Wall mounted or ceiling hanging is available |

| Thickness | Super slim, 5-10 mm only |

| Power Supplier | 12V DC |

| Light Source | High brightness LED SMD 2835 light strips |

| Size | Custom size is available |

| Advantage of Junlong LED Slim Light Box | *Ultra slim |

| *High brightness soft and even lighting | |

| *Long life and energy saving | |

| *Low consumption | |

| *Wide application | |

| Application | Widely used in office decoration, airport, station, commercial shop, shopping mall, movie house and public places, large exhibition, bathroom, dressing room,etc. |

| Service | *Installation Instruction Sheet is available *Posters with customer's working files can be printed and installed into light boxes. |

| Packing Method | Each unit will be packed in an bubble bag, several units packed into high quality master carton with protector. |

| Item | led light panel |

I. Basic Structure and Working Principle

1. Core Structure

The light guide plate is usually in the shape of a flat plate, mainly composed of the following parts:

Substrate: An optical-grade transparent plate that serves as the carrier for light propagation;

Light Incident Surface: The side that is attached to the light source (such as an LED light strip), through which light enters the light guide plate vertically;

Light Emitting Surface: The side facing the LCD panel, from which light finally exits to provide illumination for the panel;

Bottom/Side Microstructures: The bottom (or side) of the light guide plate is distributed with tiny structures (such as dots, grooves, prisms, etc.) to break the total reflection of light and guide the light to exit from the light emitting surface.

2. Working Principle

After entering the light guide plate from the light incident surface, light propagates horizontally inside the substrate due to the principle of "total reflection" (when the incident angle of light is greater than the critical angle, it does not exit the light guide plate but only reflects internally);

When light encounters the microstructures on the bottom surface, the total reflection condition is destroyed, and part of the light is refracted or scattered, changing the propagation direction and exiting vertically from the light emitting surface;

By designing the density, size, and shape of the microstructures (such as sparse dots near the light source and dense dots far from the light source), the brightness uniformity of the light emitting surface can be ensured.

Core Materials

Light guide plates need to meet requirements such as high light transmittance, low haze (adjustable in some scenarios), and good mechanical properties. Common materials include:

PMMA (Polymethyl Methacrylate, Acrylic):

It has the highest light transmittance (90%-95%), good processability, and moderate cost, making it the most commonly used material; however, its impact resistance is poor, and its temperature resistance is average (long-term operating temperature ≤80℃).

PC (Polycarbonate):

Its light transmittance is slightly lower than that of PMMA (85%-90%), but it has strong impact resistance and good temperature resistance (long-term operating temperature ≤120℃), making it suitable for scenarios with high stability requirements such as automotive and industrial equipment.

MS Resin (Methyl Methacrylate-Styrene Copolymer):

Its light transmittance is between that of PMMA and PC, with lower cost and better weather resistance, commonly used in mid-to-low-end display devices.

| Type | Processing Method | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|---|

| Printed Light Guide Plate | Printing ink dots on the bottom (screen printing) | Low cost, simple process | Low dot precision, poor brightness uniformity (≤70%); ink easy to fall off | Low-end monitors, small household appliance displays |

| Etched Light Guide Plate | Laser etching of bottom microstructures (grooves/prisms) | High precision, good brightness uniformity (≥80%); long service life | High cost of laser equipment, low processing efficiency | Mid-to-high-end monitors, laptops |

| Injection-Molded Light Guide Plate | Integral molding of microstructures during mold injection | High mass production efficiency, good consistency of microstructures; controllable cost | Complex mold design, high initial investment | Mass-produced devices such as TVs, tablets, automotive displays |

Key Performance Parameters

The performance of the light guide plate directly determines the LCD display effect, with core parameters including:

Light Transmittance: The proportion of light passing through the light guide plate, the higher the better (PMMA substrate is usually 85%-95%);

Brightness Uniformity: The difference in brightness in various areas of the light emitting surface, the higher the better for stable display effects (high-quality products ≥85%);

Haze: The degree of light scattering inside (high haze makes the emitted light softer, but slightly reduces light transmittance), which needs to be adjusted according to scenarios (e.g., TVs require low haze to ensure clarity, automotive screens require high haze to prevent glare);

Thickness: Under the trend of lightness and thinness, the mainstream thickness has developed from 1mm-5mm to below 1mm (such as the thickness of light guide plates for mobile phone LCDs ≤0.5mm);

Temperature Resistance: It needs to adapt to the working environment (-20℃-60℃ for conventional, -40℃-85℃ for automotive use).

Application Scenarios

The LCD backlight light guide plate is the "heart" of realizing uniform light emission of LCDs, widely used in all devices that rely on LCD displays:

Consumer Electronics: Laptops, desktop monitors, LCD TVs, tablets, e-book readers;

Mobile Devices: Some LCD screen mobile phones (such as mid-to-low-end models), smart watches;

Automotive Displays: Car central control screens, instrument panels, head-up displays (HUD);

Industrial and Medical Fields: Instrument displays, medical monitors;

Outdoor Displays: Billboards, self-service terminals (such as ATMs, ticket machines).

Certificates

Shipping and Payment

FAQ

1. The screen brightness is uneven. Is it a problem with the light guide plate?

Very likely. Uneven brightness may be caused by unreasonable microstructure design of the light guide plate, scratches and impurities on the surface, or misalignment with the LED light strip. Repairing or replacing the light guide plate can usually solve the problem.

2. Which material is better for the light guide plate, PMMA or PC?

Choose PMMA for daily equipment (TV, computer): higher light transmittance (brighter) and low cost.

Choose PC for automobiles and industrial equipment: drop-resistant, high-temperature resistant, and more durable.

3. Can the light guide plate be reused or recycled?

If it is not damaged, it can be washed and reused (for example, during repair).

The material (PMMA/PC) can be recycled and reused, but the performance will decrease after recycling, and it is generally not used in high-end display devices.

4. Does the light guide plate affect the thickness of the screen?

It has a great impact. The traditional light guide plate is 3-5mm thick, and now the ultra-thin version (0.3-1mm) can make the screen thinner and lighter, suitable for mobile phones and thin TVs.

5.How long can the light guide plate last?

Generally 5000-50000 hours. High temperature, direct ultraviolet rays or bumps will shorten its lifespan. Good heat dissipation and protection can extend its service life.

Hot Tags: LCD Backlight Light Guide Plate suppliers, factory, customized, price, in stock